Template:Oxygen sensor test

From Bioblast

- Oxygen sensor test

- The oxygen sensor test starts in an open chamber.

- 1. Before final equilibration, perform a stirrer test [F9], switching both stirrers automatically off for 30 s.

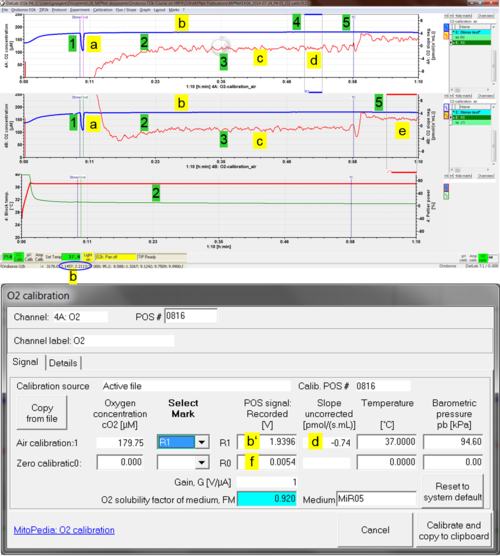

- 2. About 20 minutes are required for air equilibration after temperature equilibration of the incubation medium, visualized as stabilization of the Peltier power (Fig. Quality control; time scale is 01:10 hh:mm).

- Quality control label a: Upon automatic re-start of the stirrer (On), the increase of the oxygen signal should be rapid and monoexponential.

- Quality control label b: The raw signal (blue plot; 1 V = 1 µA at Gain 1) should be 1 to 3 V at 25 to 37 °C at sea level up to 1000 m (pb 101 to 90 kPa). At a Gain setting of 2 the raw signal [V] is multiplied by 2.

- 3. Within 40 minutes, the oxygen signals should be stable with an O2 slope (uncorrected) close to zero.

- Quality control label c: Signal noise should be low, reflected in a noise of the O2 slope (red plot) within ± 2 (± 4 is acceptable) pmol∙s−1∙mL−1 at a data recording interval of 2 s and 40 data points selected for calculation of the slope.

- 4. Set a mark on the oxygen signal (R1) and click on O2 Calib. to open the DatLab O2 calibration window (MiPNet06.03 POS-calibration-SOP).

- Quality control label d: The slope uncorrected should be within ± 1 pmol∙s−1∙mL−1 averaged across the section of the experiment marked as R1 for air calibration (d). The recorded POS signal should be close to the previous calibration under identical experimental conditions. See O2-Calibration window (see Fig. right, label b’).

- 5. Close the chamber and if required, perform a zero oxygen calibration.

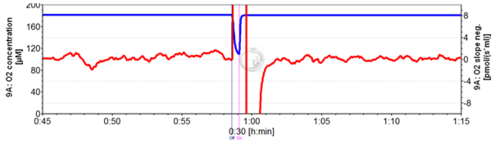

- Quality control label e: After closing the chamber, select plot Y2 and set mark J°1. O2 slope neg. should be within 3.0 ± 1 pmol∙s−1∙mL−1.

- O2 slope neg. values higher than 4.0 pmol∙s−1∙mL−1 indicate:

- » Biological contamination.

- » Air bubbles in the Closed chamber: switch on the illumination of the O2k and inspect the O2k-Chamber through the front window. Remove any air bubbles.

- » A large volume of medium collected in the receptacle of the stopper: siphon off excess medium.

- » A larger chamber volume: check O2k-Chamber volume calibration.

- O2 slope neg. values higher than 4.0 pmol∙s−1∙mL−1 indicate:

- Quality control label f: The zero signal at mark R0 for zero calibration should be <2 % of R1 (stable at <5 % is acceptable).

- 3. Within 40 minutes, the oxygen signals should be stable with an O2 slope (uncorrected) close to zero.