MiPNet06.03 POS-calibration-SOP

Template:OROBOROS navigation line page name

| Polarographic oxygen sensors: calibration, accuracy and quality control SOP. »Bioblast pdf« |

» Versions

OROBOROS (2015-05-10) Mitochondr Physiol Network

Abstract: Gnaiger E (2015) Polarographic oxygen sensors: calibration, accuracy and quality control SOP. Mitochondr Physiol Network 06.03(13):1-8.

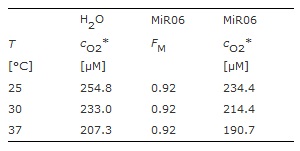

High-resolution respirometry critically depends on accurate calibration of the polarographic oxygen sensors which respond to partial oxygen pressure. Expressing the oxygen signal in terms of partial pressure has several advantages, but respiration is expressed in molar units related to biochemical stoichiometries. Conversion of oxygen partial pressure to oxygen concentration requires accurate information on oxygen solubilities in experimental incubation media. Absolute errors up to 10% are commonly found in the established literature. The oxygen solubility of mitochondrial respiration medium MiR06 relative to pure water (oxygen solubility factor, FM) is 0.92, accurately determined (for MiR05, i.e. MiR06 without catalase; MiPNet14.13) at 37 °C and 30 °C. At air saturation at standard barometric pressure (100 kPa) and 37 °C, the partial oxygen pressure is 19.63 kPa, and the oxygen concentration is 190.7 µM in MiR06. A clean and ready-to-use O2k-Chamber is a requirement for saving time and quickly calibrating the polarographic oxygen sensors.

- » Product: OroboPOS, Oxygraph-2k, O2k-Catalogue

• O2k-Network Lab: AT_Innsbruck_OROBOROS

Labels: MiParea: Instruments;methods

HRR: Oxygraph-2k, Protocol"Protocol" is not in the list (Oxygraph-2k, TIP2k, O2k-Fluorometer, pH, NO, TPP, Ca, O2k-Spectrophotometer, O2k-Manual, O2k-Protocol, ...) of allowed values for the "Instrument and method" property.

O2k-SOP

This article is cited in

- Rodriguez JV, Pizarro MD, Scandizzi AL, Guibert EE, Almada LL, Mamprin ME (2008) Construction and performance of a minibioreactor suitable as experimental bioartificial liver. Artif Organs 32:323-8. »PubMed 18370948«

Further details

- O2k-Manual: »MiPNet19.18D_O2k-Calibration«

- Next step of instrumental quality control: »MiPNet14.06 InstrumentalBackground«

- Forstner H, Gnaiger E (1983) Calculation of equilibrium oxygen concentration. In: Polarographic Oxygen Sensors. Aquatic and Physiological Applications. Gnaiger E, Forstner H (eds), Springer, Berlin, Heidelberg, New York:321-33. »Bioblast Access«

O2 sensor test

MitoPedia O2k and high-resolution respirometry:

O2k-Open Support

The O2 sensor test is described as an OroboPOS standard operating procedure: »Bioblast pdf (on top of page).

When should an O2-sensor test be performed?

- After switching on the O2k, every day: air calibration and stirrer test.

- Zero oxygen calibration: from time to time over weeks; bracketing zero oxygen calibrations when working at low oxygen.

- After application of a new membrane and O2-sensor service: In some cases, the signal of the OroboPOS improves (higher signal stability, less noise, shorter response time), when the O2k remains switched on over night (O2k-Chambers filled with 70% EtOH).

- During troubleshooting, particularly when switching components between the two chambers, a quick sensor test is performed after each step (stirrer test, sensor signal).

Main criteria for sensor performance

Oxygen signal at air saturation

The oxygen signal at air saturation is an important performance criterion. It is assessed in the sensor test during the preparation for each experiment.

The uncalibrated oxygen sign (raw signal) depends on the oxygen concentration and the gain. The numerical value of the calibrated oxygen signal depends on the raw signal and the POS calibration. The optical appearance of the calibrated oxygen signal also depends on the used scaling.

If there are any doubts about the oxygen signal, please check first Raw signal at air saturation. If the raw signal is in the expected range for the chosen gain and stable the problem is probable a software setting. In this case check that

- the gain is set correctly (as described in Raw signal at air saturation

- a proper POS calibration has been performed for this chamber with this sensor at this gain. If necessary repeat air calibration and zero calibration

If the oxygen signal at air saturation, R1 [ raw signal ; V], is suddenly very different compared to previous calibrations see also Suddenly changing oxygen signal.

For a discussion about the flux at air saturation see also Flux at closed chamber near to air saturation and Flux at open chamber.

- Raw signal at zero oxygen

- Signal stability: drift and noise

OroboPOS technical support

MitoPedia O2k and high-resolution respirometry:

O2k-Open Support

If a Stirrer test shows a slow response of the sensor, see more details in Slow responding sensor.

As the heart of the OROBOROS O2k the OroboPOS is the prime suspect when technical problems are encountered. However, frequently problems can be traced either to inadequate software settings or to other hardware components, such as the POS connector). Therefore, it is important to locate the problem, primarily with a Sensor test.

OroboPOS technical support pages

The query description has an empty condition.

Problems that require a full Sensor test to locate the problem

- Unstable O2 signal.

- Unstable O2 flux.

- High O2 signal at air saturation.

- High O2 signal at zero oxygen.

Special cases: no further localization necessary

- Slow responding sensor, if observed in a Stirrer test. Note: The stirrer test is part of the sensor test. It is therefore recommended to do a full Sensor test whenever problems are encountered.

General trouble shooting procedure for the OroboPOS

Confirm the problem by doing a Sensor test in the absence of biological material

Case 1.A: No problem was visible in the Sensor test

Check the following DatLab settings:

- Gain (O2 channel)

- POS calibration

- Scaling

If the problem is not visible when observing the Raw signal but is visible when observing the calibrated oxygen signal, then there is probably a problem with the POS calibration.

Case 1.B: The problem was visible in the Sensor test

- Proceed to Locate the Problem and continue as shown below.

Case 2.A: The problem could be localized on the OroboPOS

Solutions: Follow the instructions for oxygen sensor service MiPNet08.04. Apply contact oil to the gold pin and thread connecting the OroboPOS and sensor connector. After a sensor service or after applying a new membrane, repeating the sensor test. In some cases the O2k may be left running over night to achieve a stable signal, as seen by a repeated sensor test. If all service precautions fail to solve the problem, the OroboPOS has to be sent to OROBOROS INSTRUMENTS for further service (a recovery cannot be guaranteed), or a new sensor is applied.

Case 2.B: The problem was not located on the POS

Solutions: If the problem was localized on an other component follow the instructions for this component. If you could not locate the problem, contact OROBOROS INSTRUMENTS.

Response time of the POS

MitoPedia O2k and high-resolution respirometry:

O2k-Open Support

The response time of the Polarographic oxygen sensor is assessed in the Stirrer test that is part of a full Sensor test. A quantitative interpretation of the stirrer test will yield the time constant of the sensor. Such a quantitative calculation is indeed necessary for kinetic work. However, to access the suitability of a sensor for standard steady state work each user will soon gain the necessary experience to judge the outcome of a stirrer test.

- >> Example: Download here.

For how to improve the response time of a POS, see Slow responding sensor.

The response time of the sensor is just one of several factors determining the time resolution.

Stirrer test

MitoPedia O2k and high-resolution respirometry:

O2k-Open Support

The response time of the POS can be most conveniently checked by a stirrer test, see MiPNet06.03_POS-Calibration-SOP, section 3. The stirrer test is part of the Sensor test and of our proposed quality checks before every experiment described in the link above. see If the results of a stirrer test are not satisfactory the procedures suggested for a Slow responding sensor should be followed. DatLab supports an automatically controlled stirrer test [F9].

Background information: After switching off the stirrer the electrolyte reservoir will quickly be depleted of oxygen by the oxygen consumption of the sensor. Oxygen can only reach the sensor now in a unstirred diffusion process, therefore a new and lower equilibrium O2 concentration is established in the vicinity of the sensor. After switching the stirrer on again the O2 concentration near the sensor is quickly brought back to the same level as elsewhere in the chamber, however the sensor takes some time to respond to this change. Thus the response time of the sensor can be determined. A stirrer tests does not influence the O2 concentration in the entire chamber. A stirrer test can not be at a chamber oxygen concentration of zero (or near zero) because no change in the O2 signal will result.